Braitheann cóireáil fuíolluisce tionsclaíoch go mór ar theicneolaíochtaí idirscartha soladacha leachtacha éifeachtúla chun a chinntiú go gcomhlíontar rialacháin chomhshaoil agus chun éifeachtúlacht an phróisis a bharrfheabhsú. Among the most effective solutions are hydraulic screen separators, industrial sieve systems, and automated sludge dewatering screens. Each of these technologies offers unique advantages depending on application requirements.

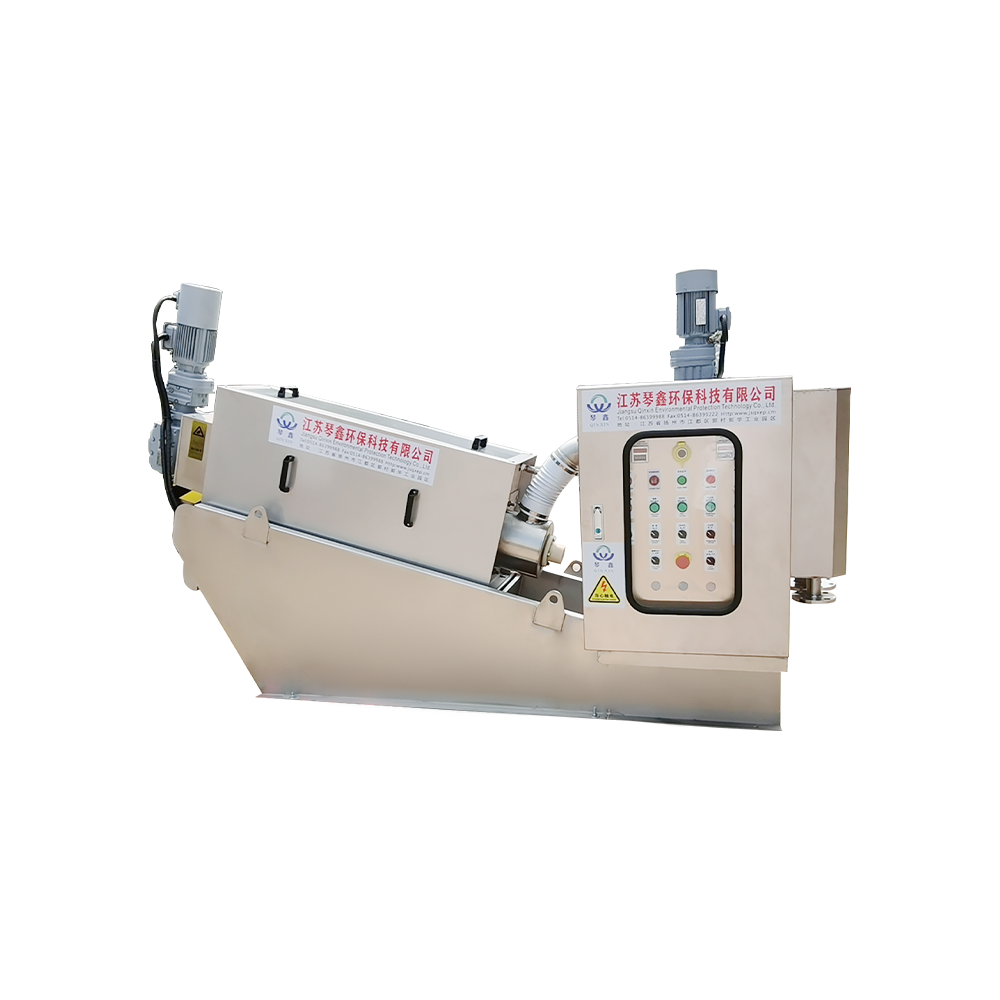

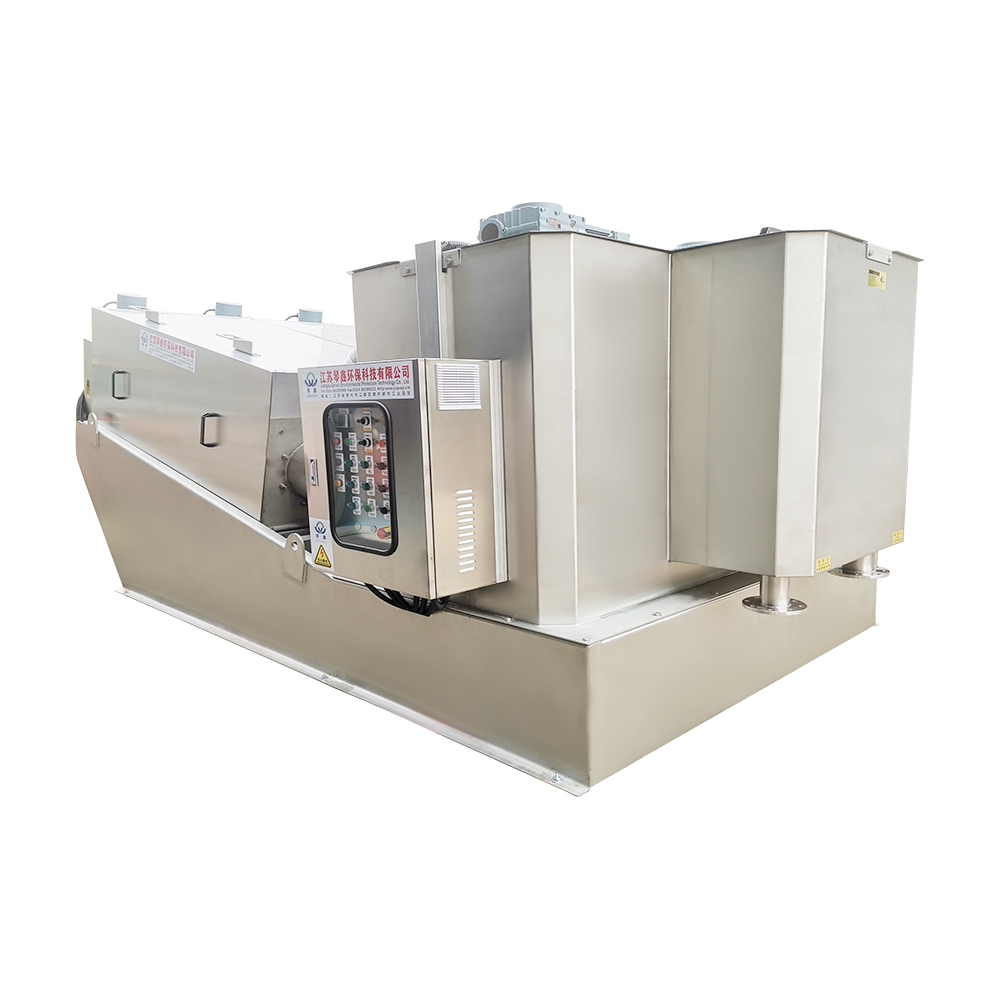

Inclined Screen Hydro-Cyclone Hydraulic Solid-Liquid Separator Equipment/Machine QXSLS-120T

1. Hydraulic Screen Separator for Wastewater Treatment : High Efficiency with Low Maintenance

Úsáidtear deighilteoirí scáileáin hiodrálacha go forleathan i gcóireáil fuíolluisce cathrach agus tionsclaíoch mar gheall ar a gcumas chun rátaí sreafa arda a láimhseáil agus solaid mhín a bhaint. These systems utilize a rotating drum or static screen with water pressure to separate suspended particles.

Príomhbhuntáistí:

High filtration efficiency (removes particles as small as 0.5mm).

Low energy consumption compared to centrifugal systems.

Self-cleaning design, reducing manual maintenance.

Ideal Applications:

Food & beverage processing wastewater.

Paper mill effluent treatment.

Stormwater filtration.

2. Industrial Hydraulic Sieve Separator : Robust Filtration for Harsh Environments

Is córais dualgas trom iad deighilteoirí criathar hiodrálacha tionsclaíocha atá deartha le haghaidh dálaí dúshlánacha, mar shampla mianadóireacht, próiseáil cheimiceach, agus cóireáil rith chun srutha tógála. Unlike standard screens, these separators use reinforced mesh and high-pressure water jets to prevent clogging.

Performance Comparison:

| Príomhscannán | Hydraulic Screen Separator | Industrial Sieve Separator |

|---|---|---|

| Particle Retention | 0.5mm - 5mm | 0.2mm - 3mm |

| Max Flow Rate | 500 m³/h | 300 m³/h |

| Maintenance Needs | Measartha | Low (self-cleaning) |

Best For:

Mining slurry dewatering.

Oil & gas wastewater.

Aggressive chemical effluents.

3. Automatic Sludge Dewatering Screen : Maximizing Water Recovery

Automated sludge dewatering screens are essential for reducing sludge volume and recovering reusable water. These systems use vibration or press filtration to extract moisture, significantly cutting disposal costs.

Advantages Over Traditional Methods:

Up to 70% reduction in sludge weight, lowering transport expenses.

Fully automated operation, minimizing labor input.

Compact design, suitable for space-limited facilities.

Common Uses:

Municipal sewage plants.

Textile dyeing wastewater.

Livestock manure processing.

Choosing the Right Separation Technology

The optimal solid-liquid separator depends on specific needs:

Hydraulic screen separators excel in high-flow, low-solids applications.

Industrial sieve systems handle abrasive and high-load conditions.

Automatic dewatering screens are best for sludge volume reduction.

Trí anailís a dhéanamh ar mhéid na gcáithníní, ar rátaí sreafa, agus ar éilimh an tionscail, is féidir le gnólachtaí an réiteach is éifeachtaí ó thaobh costais agus éifeachtúil a roghnú dá ndúshláin chóireála fuíolluisce. $ $

ENG

ENG

TOPA

TOPA